Your success is our mission!

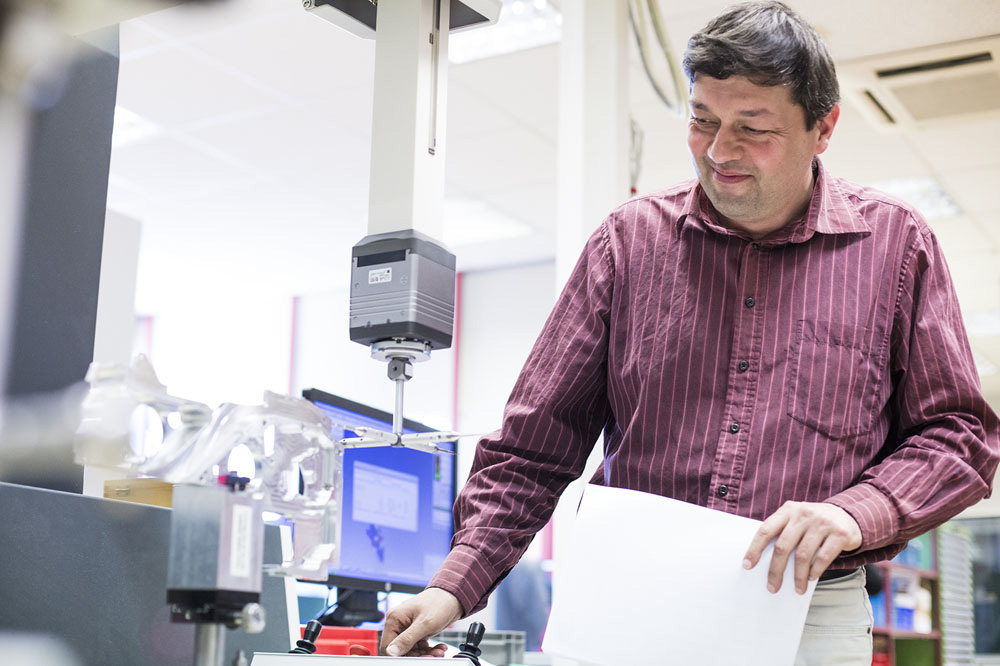

»“Good planning is half the battle”, and as we at Heppler believe quality equates to cost-efficient thoughts and deeds, we support you as the customer from as early a stage as possible on the road to an optimum product result.

We provide advice on:

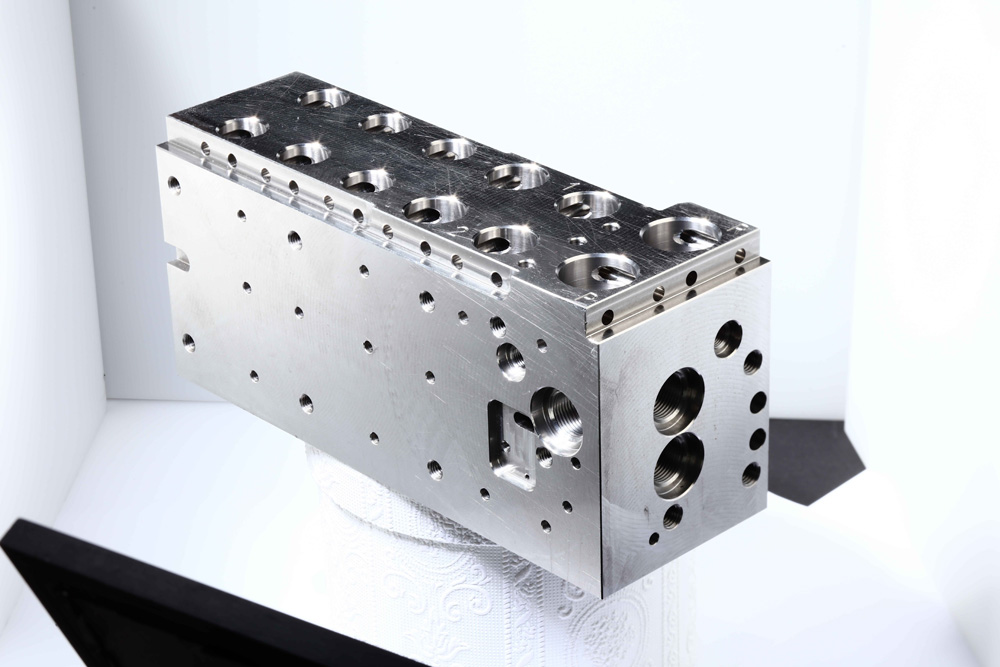

• finding a suitable product design,

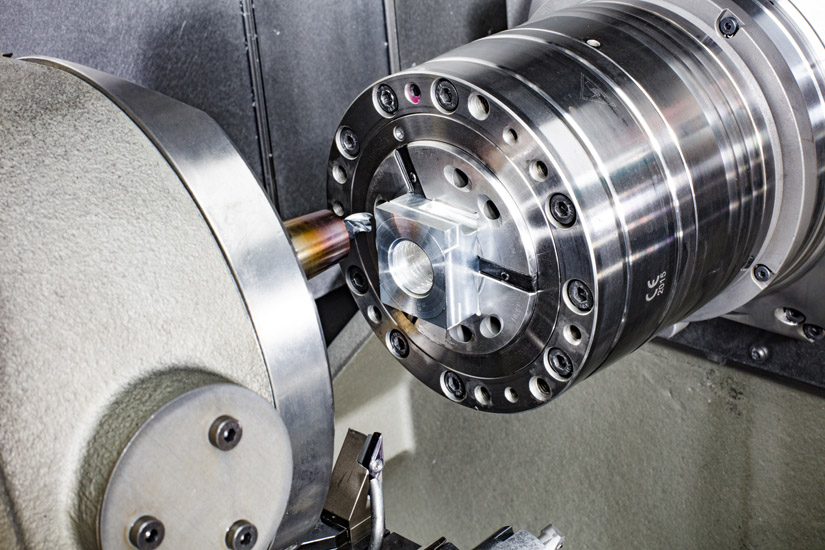

• selection of a suitable material,

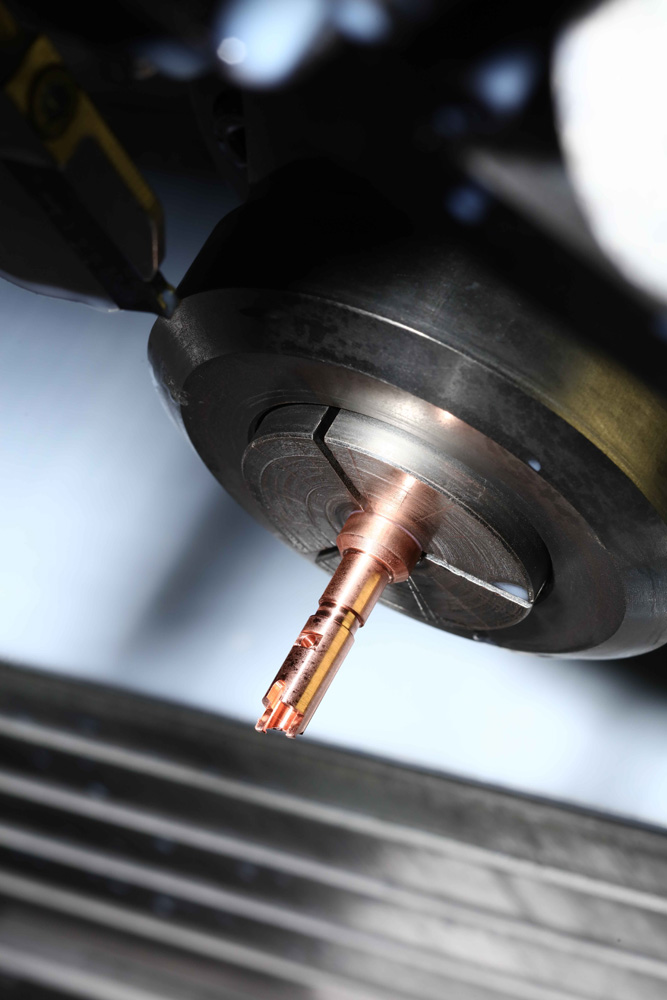

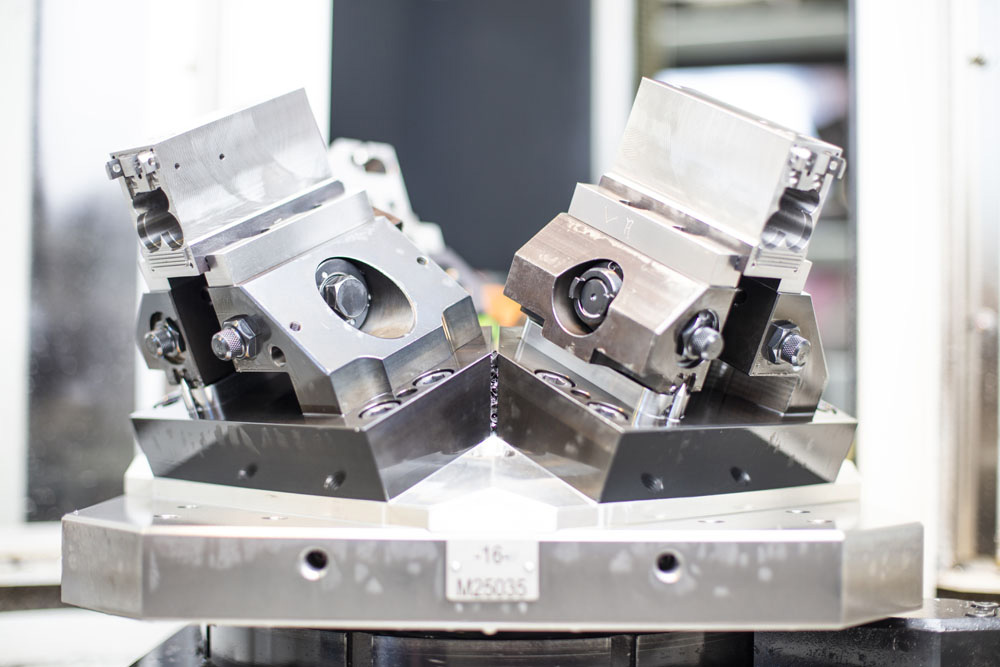

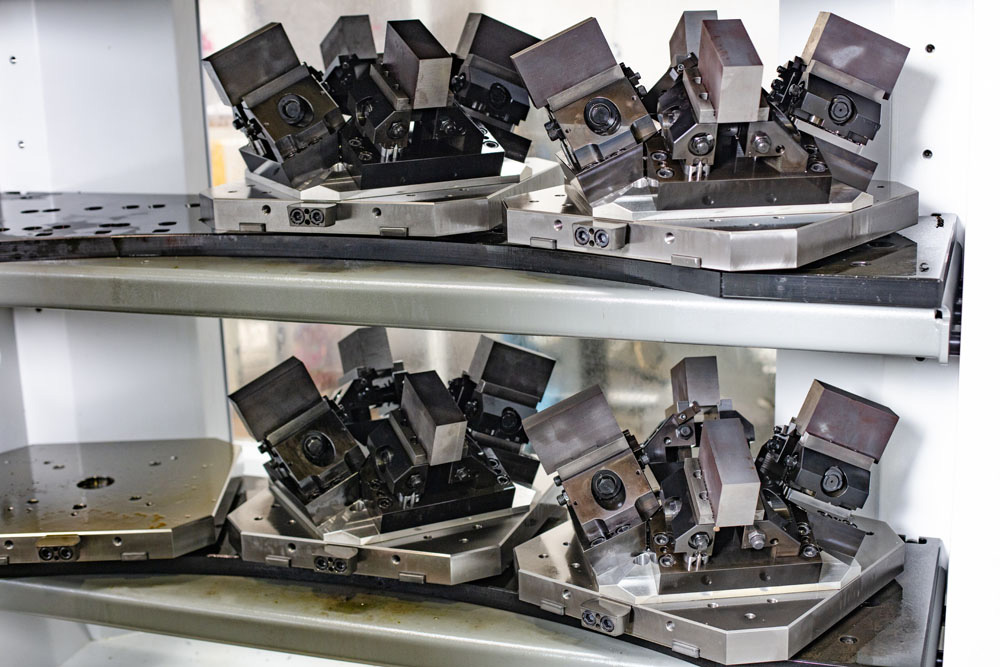

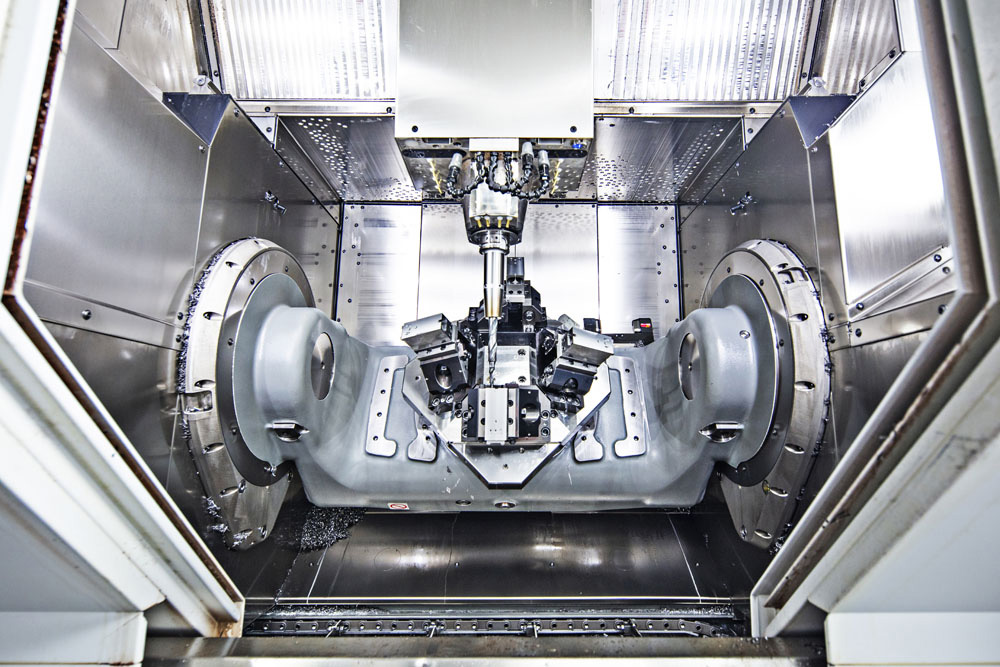

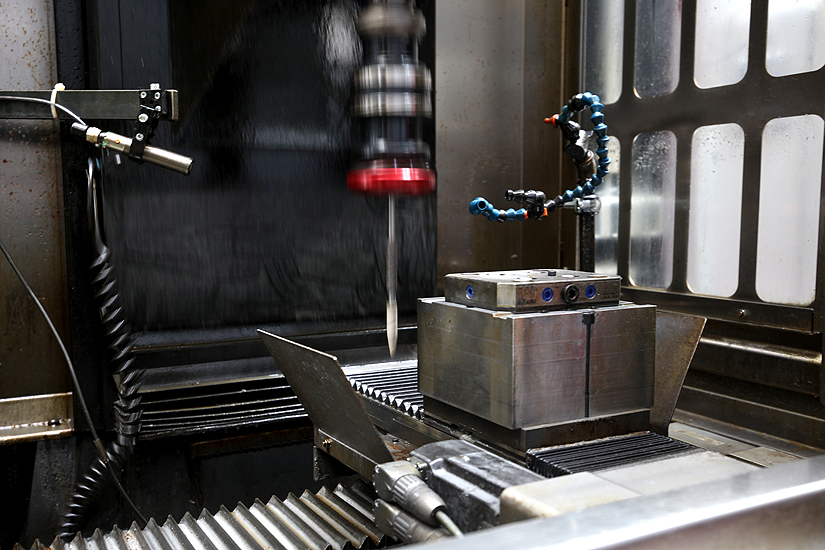

• the most economically suitable production process

...and then we produce for you!

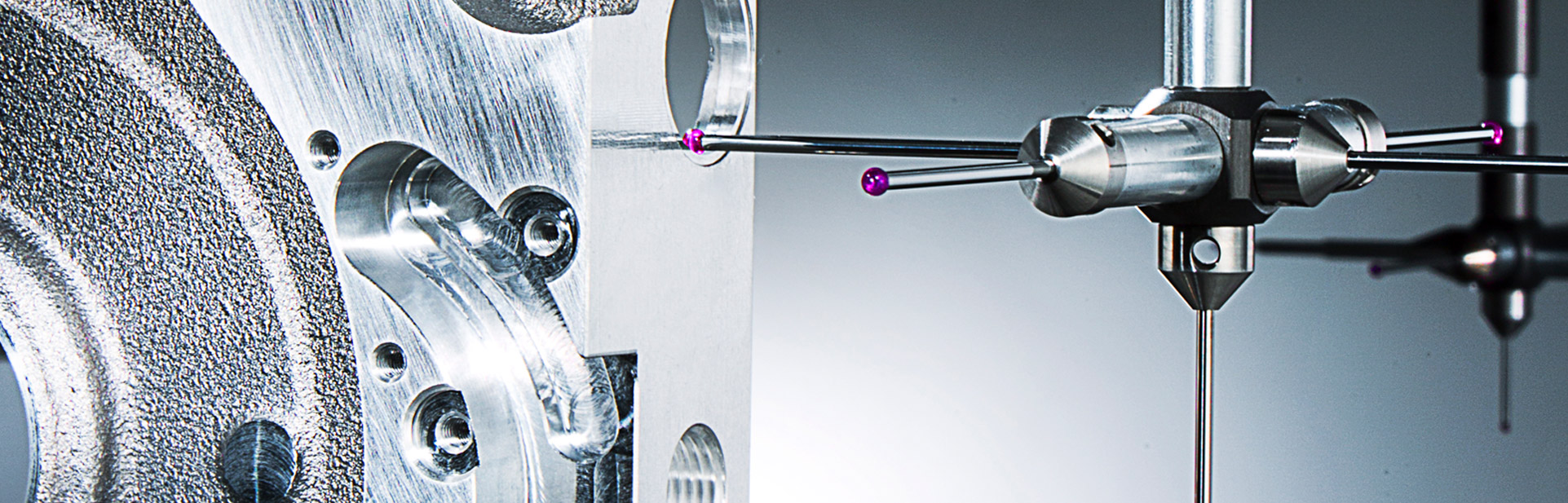

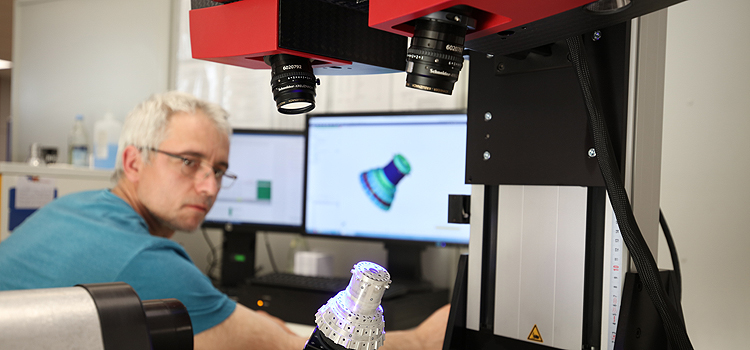

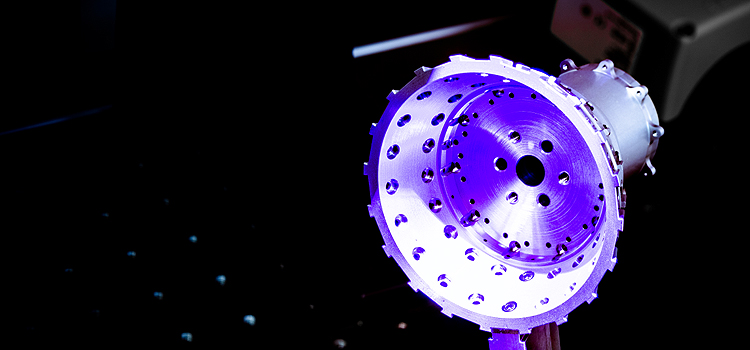

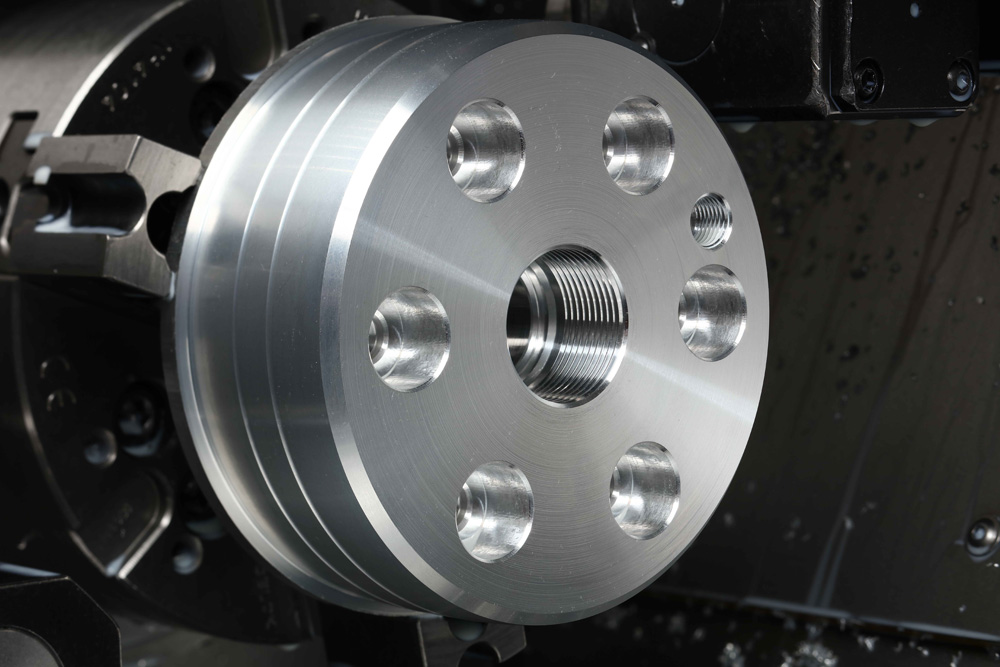

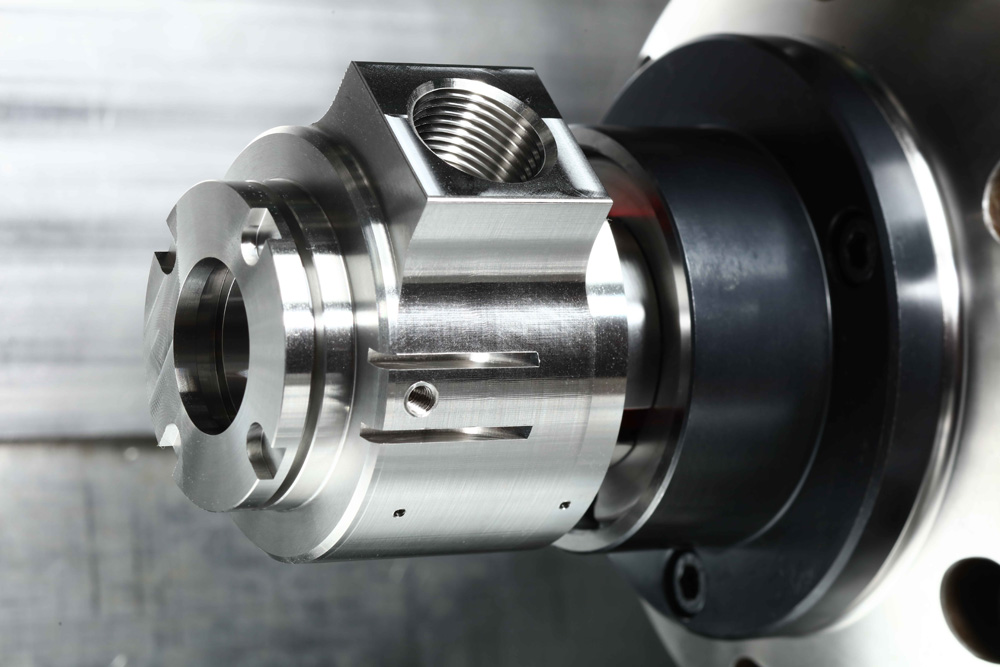

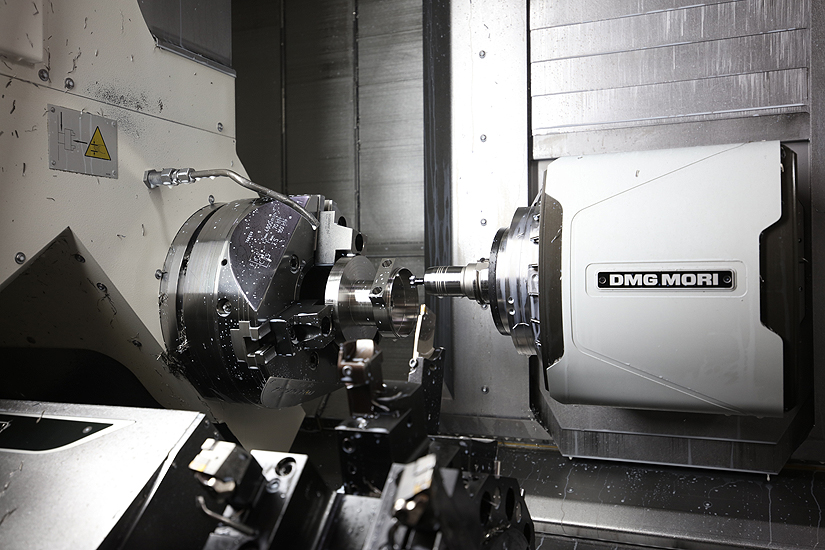

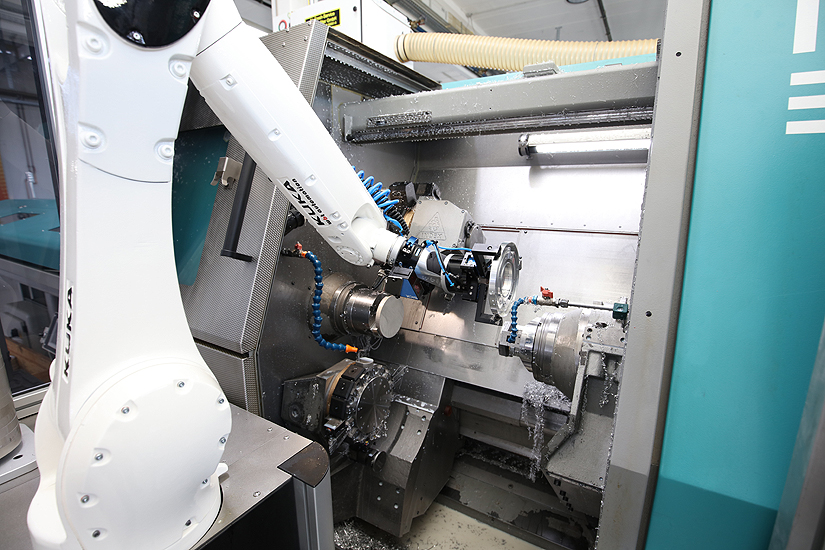

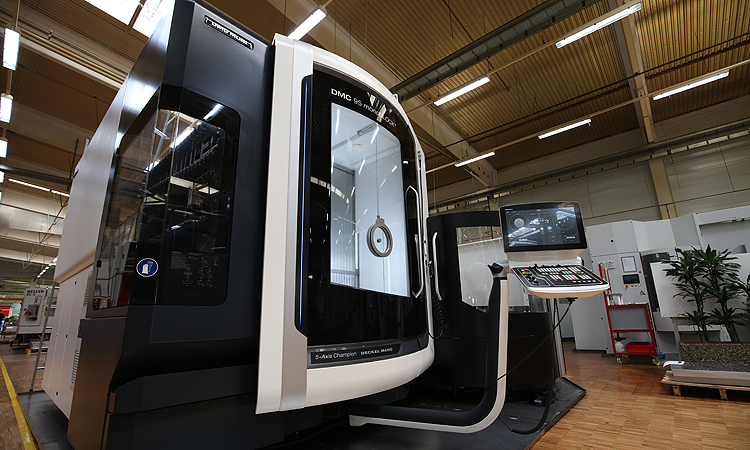

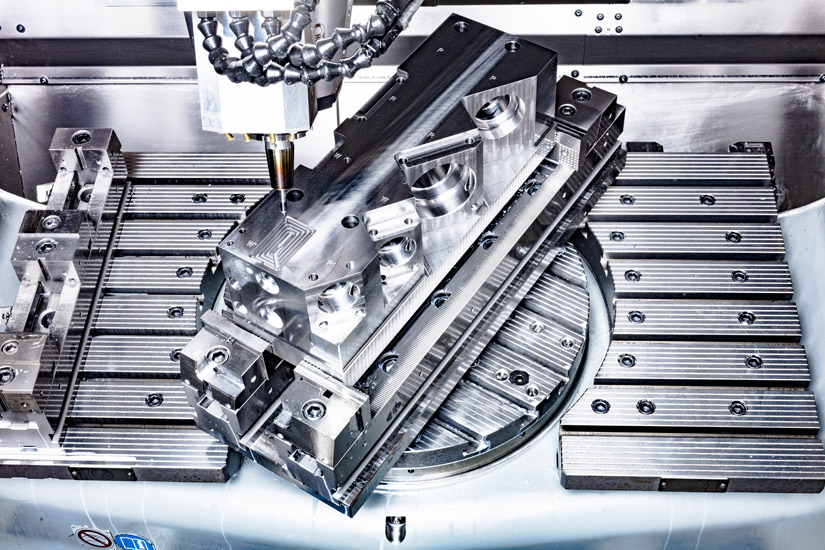

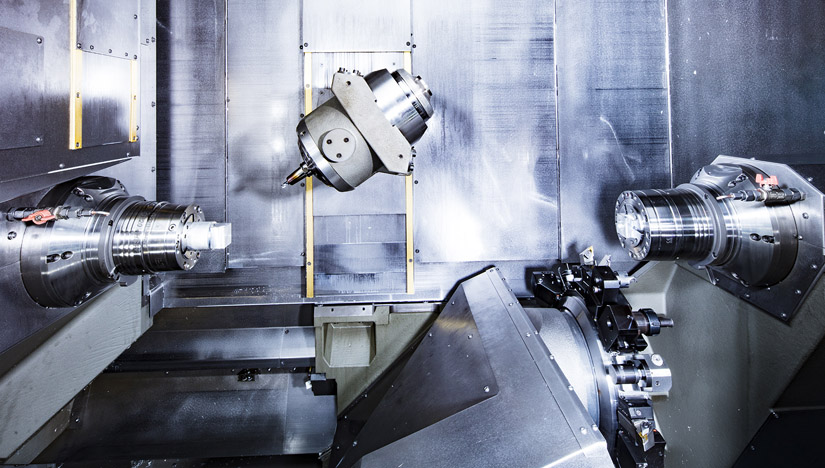

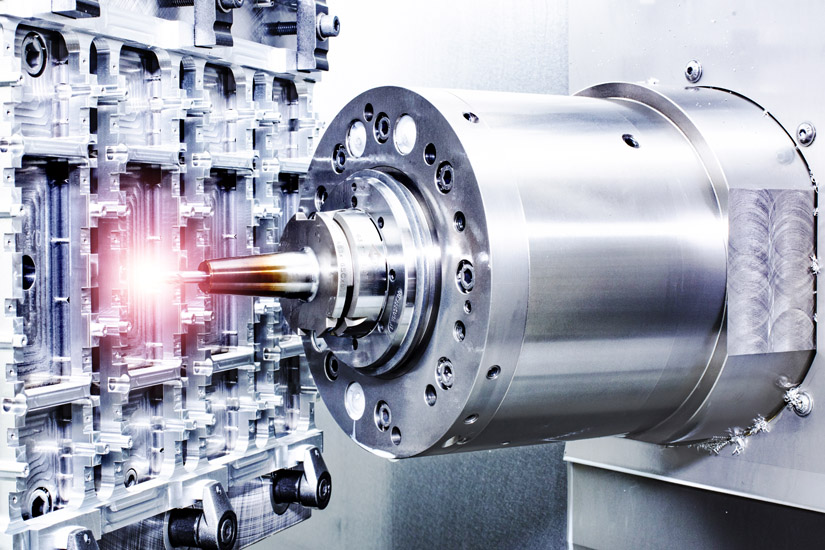

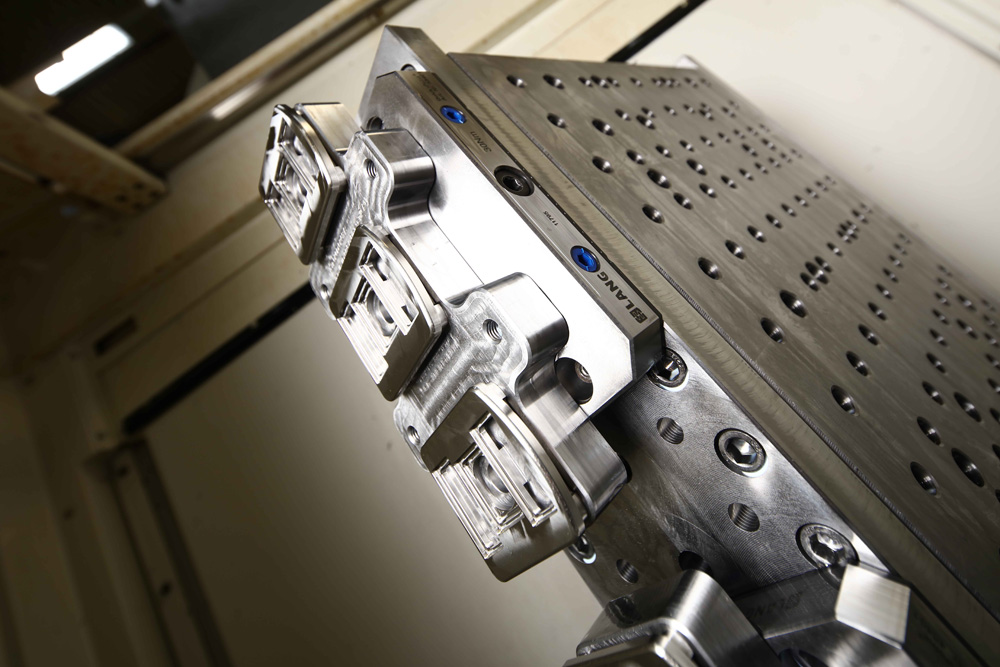

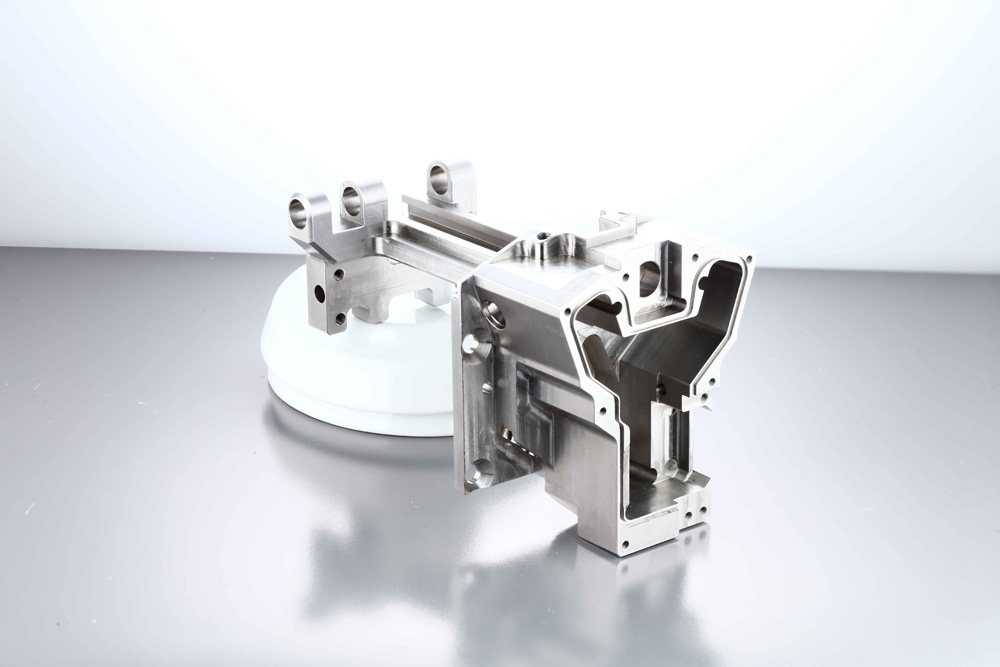

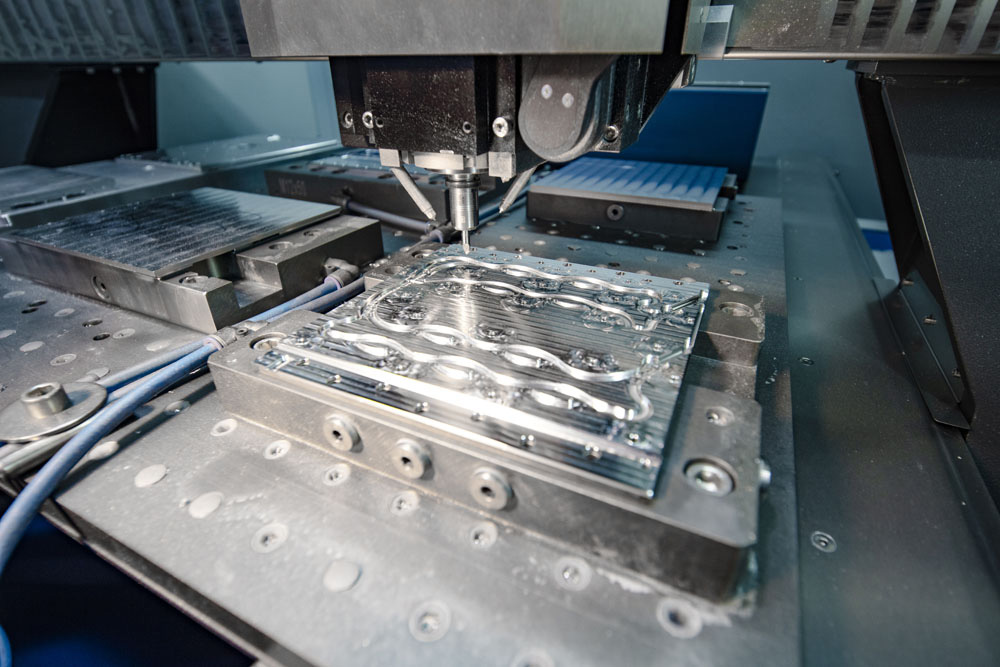

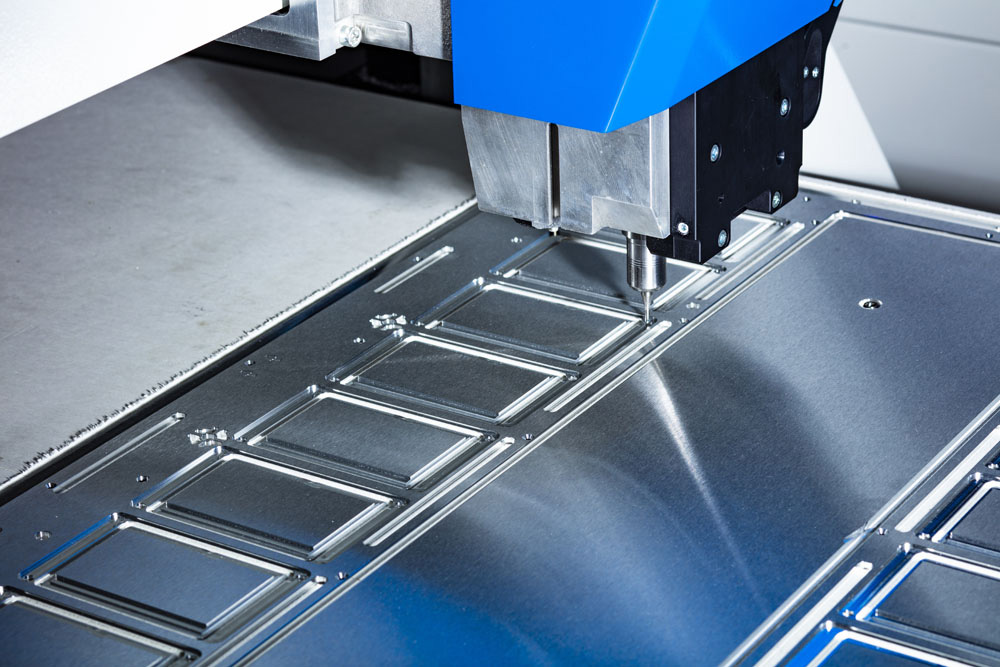

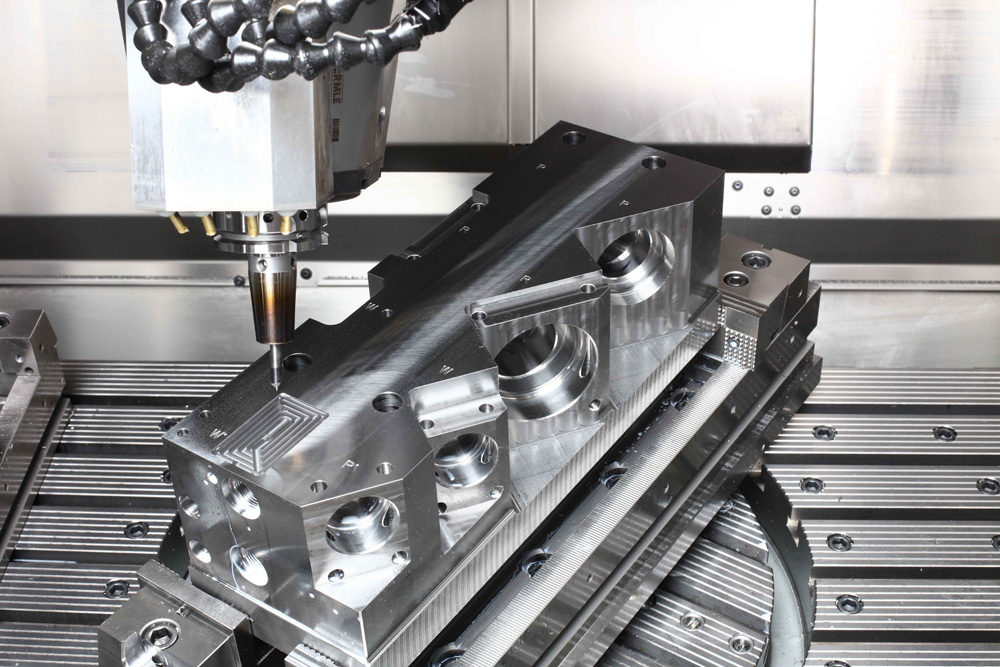

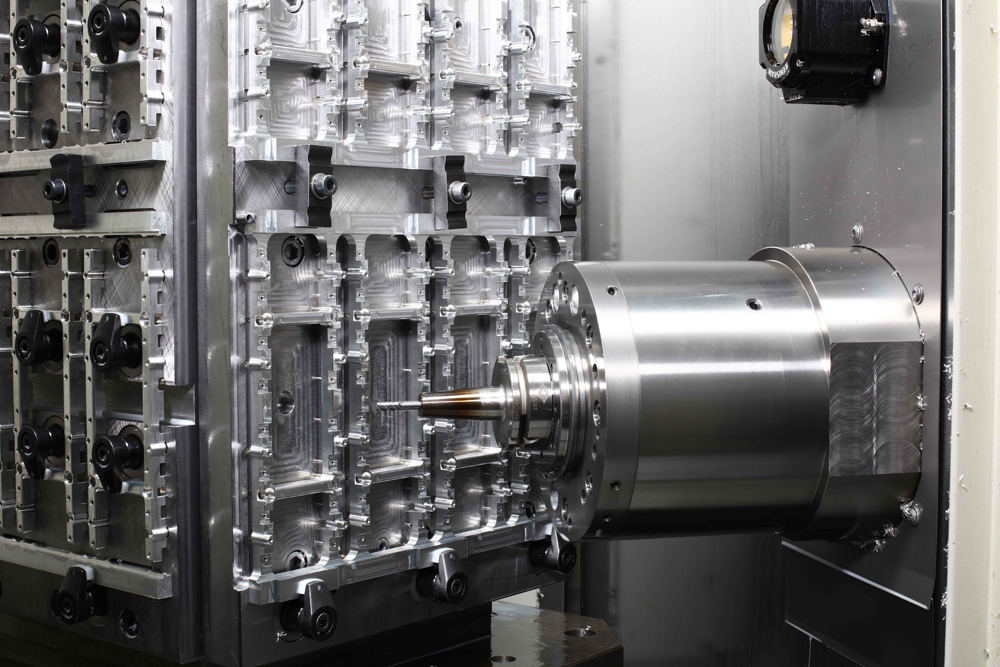

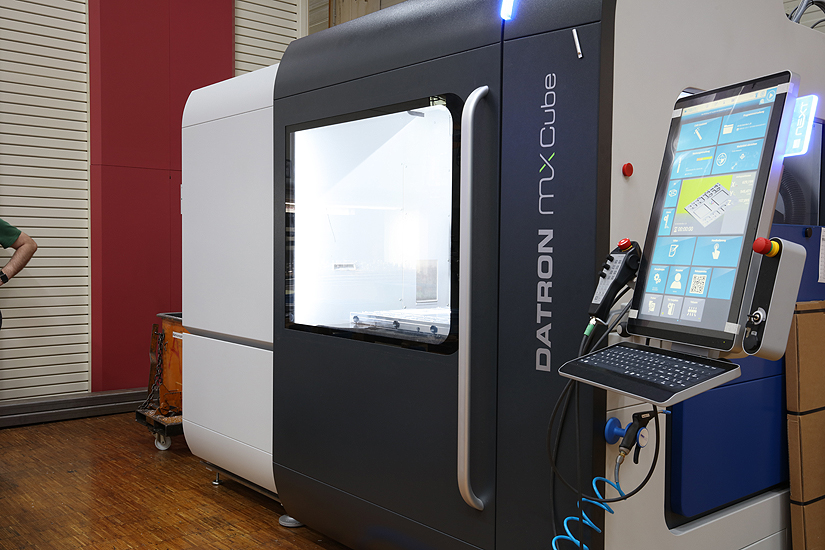

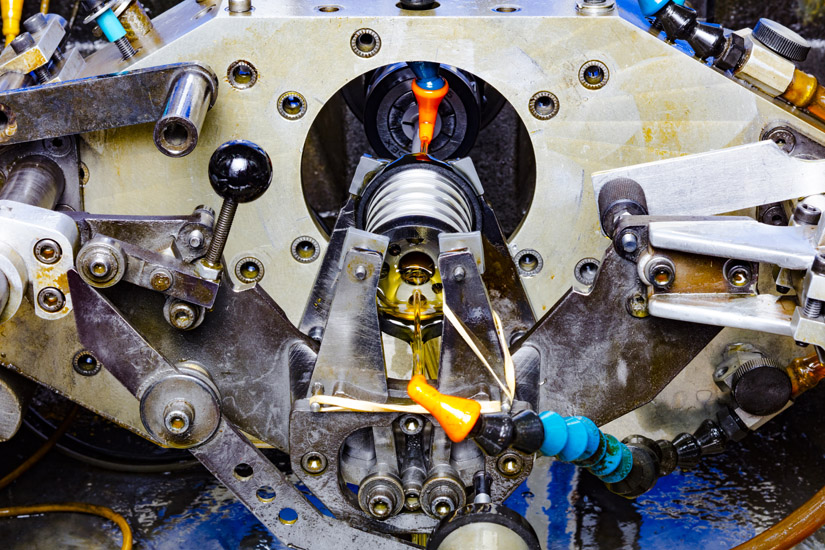

You can benefit from decades of Heppler experience and our expertise when it comes to material properties, processing chains, CNC machine controls, surface finishing and refinement and the properties of the finished workpiece. Our customers receive everything from a single source,

from the initial prototype idea to series production.

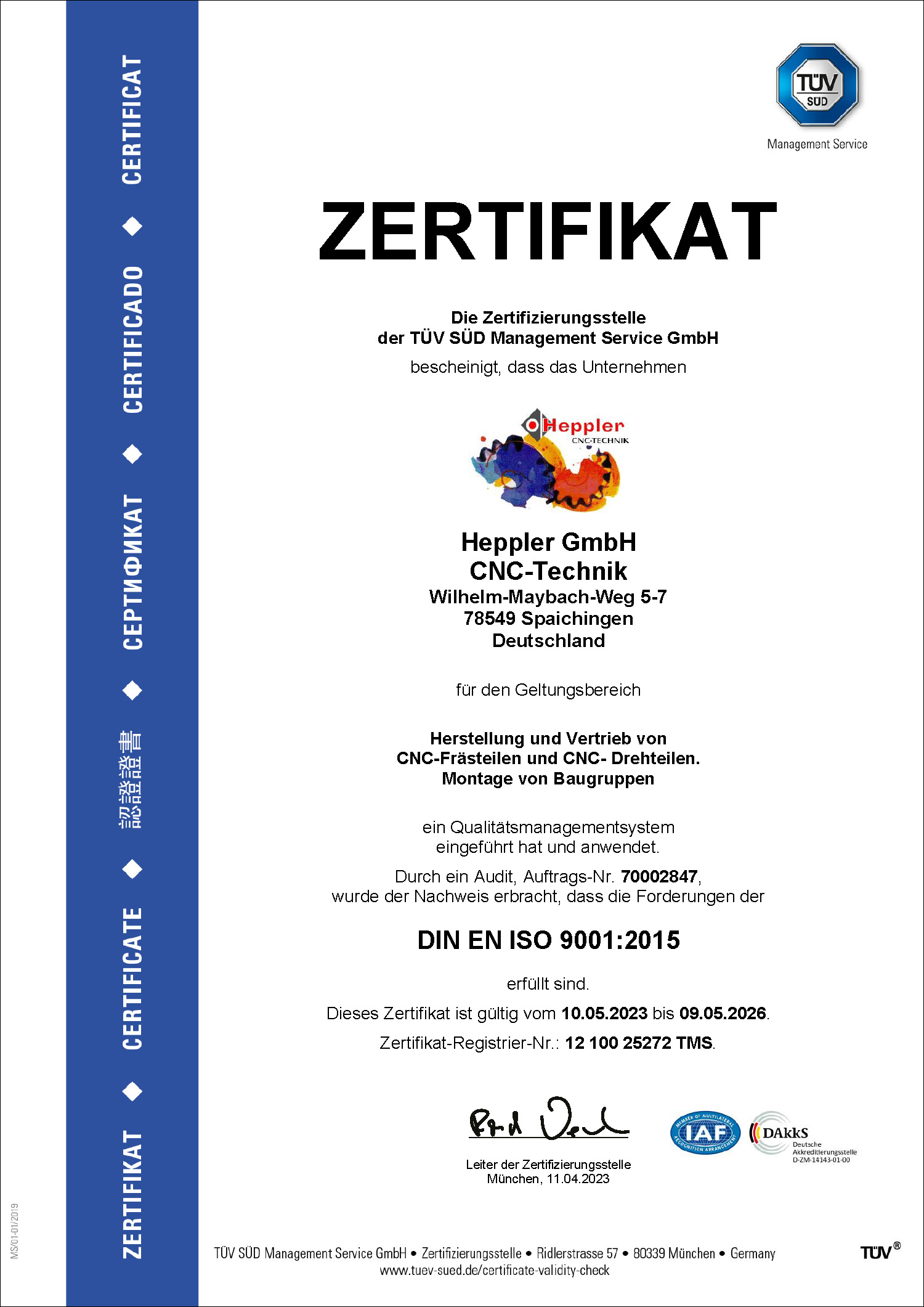

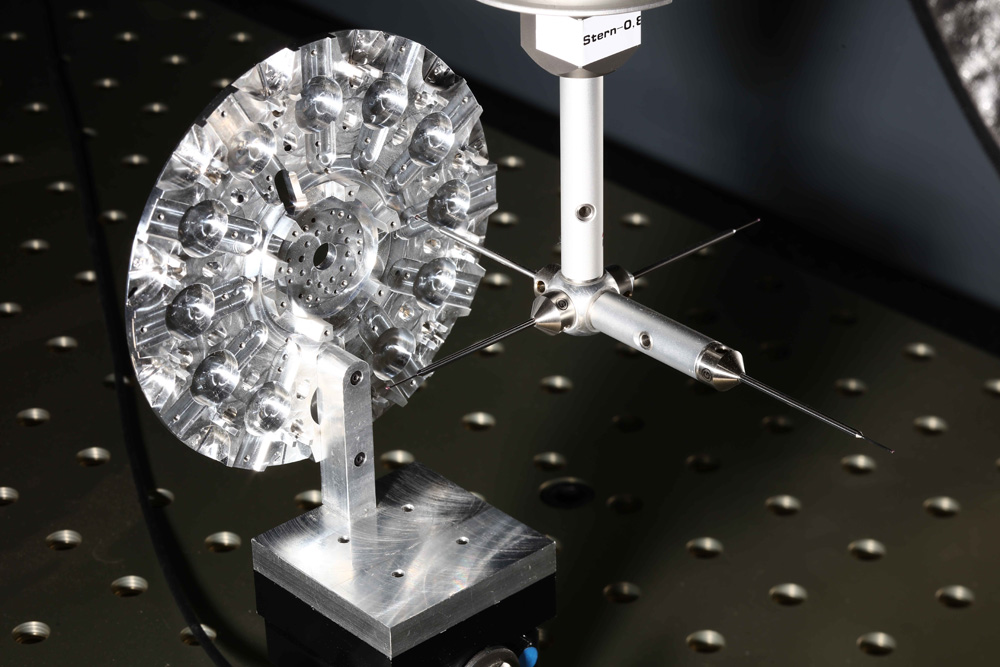

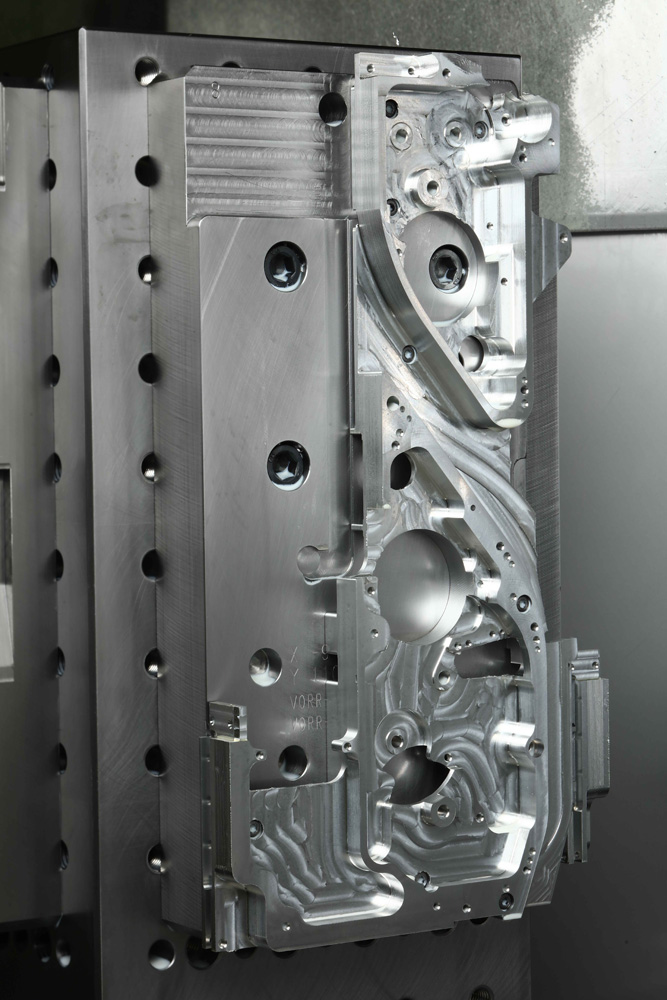

What should the ultimate product be capable of? And what is a realistic route to achieve this? The answer is found at the beginning of our cooperation through the Heppler feasibility analysis. Together, our initial step will illuminate the facts that, for example, underlie your engineering drawing, determine the options and assess the risks involved. You benefit from this: An objective assessment to realise your project. Heppler’s process optimisation commences... The Heppler Team gets to the core of the situation, asking even more questions, developing even more constructive ideas and contributing greatly to finding a solution. Process optimising leads to an optimised process. This describes precisely the optimum approach adopted in production, both with regard to the quality of the final product and cost-effective production. ...and all of this while concentrating on the answer to the decisive question: The content of our offers is based on prior analysis and consultation – while transparency during drafting is another essential criterion and, for us, an absolute MUST. It is a crucial component for target-oriented cooperation and ensures that a result of the highest quality is achieved, both in terms of material and workmanship, and consistently during the entire cooperative effort. ANALYSIS

Consulting

What should the ultimate product be capable of?Offers